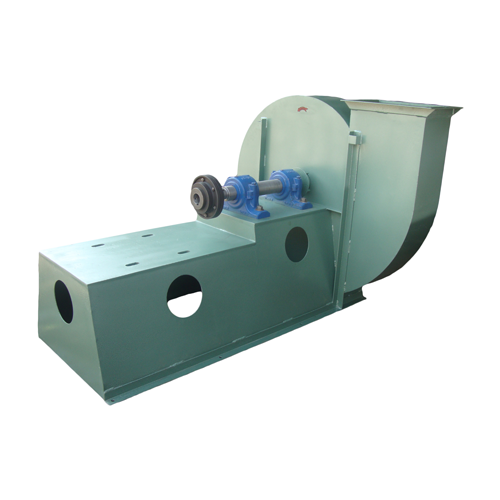

Centrifugal Blowers are the perfect solution for vacuum or compressed air applications. Centrifugal blowers provide dry, clean, oil-free air and require low energy consumption. Unlike compressed air systems, this series is safe to run at low pressure, and allows for increased production speeds or levels. The blower comes with ceramic hybrid bearings, 360 degree rotatable outlet discharge, easy to remove steel bearing housing assembly, and zinc planted steel motor pulley.

Centrifugal Blowers are also known as Centrifugal Fans.The kinetic energy produced by the impellers of the Centrifugal Blower Fan on rotation is used to increase the pressure of the air stream, which in turn moves them against the resistance caused, by ducts, dampers and other components.

Centrifugal fans accelerate the airstream radially, changing the direction typically by 90o of the airflow. At a constant fan speed, centrifugal fans pump a constant volume of air. They are capable of operating over a wide range of conditions.

WORKING PRINCIPLE

Air enters the center of a spinning impeller and is divided between the impeller’s vanes. As the impeller turns, it accelerates the air outwards using centrifugal force. This high-velocity air is then diffused and slowed down in the surrounding blower housing to create pressure.